Sublimation Dye Patch Hat - Custom Creations

Have you ever considered giving your headwear a truly unique touch, something that really stands out from the crowd? For folks looking to add a bit of personal flair or a special message to their caps, there is a pretty cool method making waves. We are talking about the sublimation dye patch hat, a way to get designs onto your favorite hat that look incredibly vibrant and, in a way, just seem to last. It is a neat trick that lets images and colors sink right into the fabric, making them a part of the hat itself rather than just sitting on top.

This process, you know, it is a bit different from your typical printing methods. Instead of just laying ink down on the surface, which can sometimes crack or fade over time, this technique uses a special kind of dye that, basically, turns into a gas. This gas then bonds with the material, creating a design that is remarkably durable and feels very smooth to the touch. It is kind of like magic, really, seeing how a picture goes from paper to fabric with such clarity, and you can get some truly amazing results for your custom sublimation dye patch hat.

So, if you have been curious about how some hats seem to have such lively, detailed pictures that do not peel off, or perhaps you are thinking about making some custom hats for your team, business, or just for yourself, then you are in the right spot. We are going to explore what makes a sublimation dye patch hat so special, how this interesting process actually works, and why it might be just what you are looking for to bring your headwear visions to life. It is honestly pretty straightforward once you get the hang of it, and the possibilities are quite wide open.

- Unveiling The Life Of Arbaaz Khan The Journey Begins

- Exploring The Ella Langley And Riley Green Relationship

- Exploring The Iconic Trading Places Film Cast

- Unraveling The Mystery Who Is Kellen Moores Wife

- Unveiling The World Of Dylan Bratz The Iconic Doll That Redefined Fashion

Table of Contents

- What is Sublimation and How Does it Work for a Dye Patch Hat?

- Why Choose a Sublimation Dye Patch Hat?

- Are Sublimation Dye Patch Hats Right for Everyone?

What is Sublimation and How Does it Work for a Dye Patch Hat?

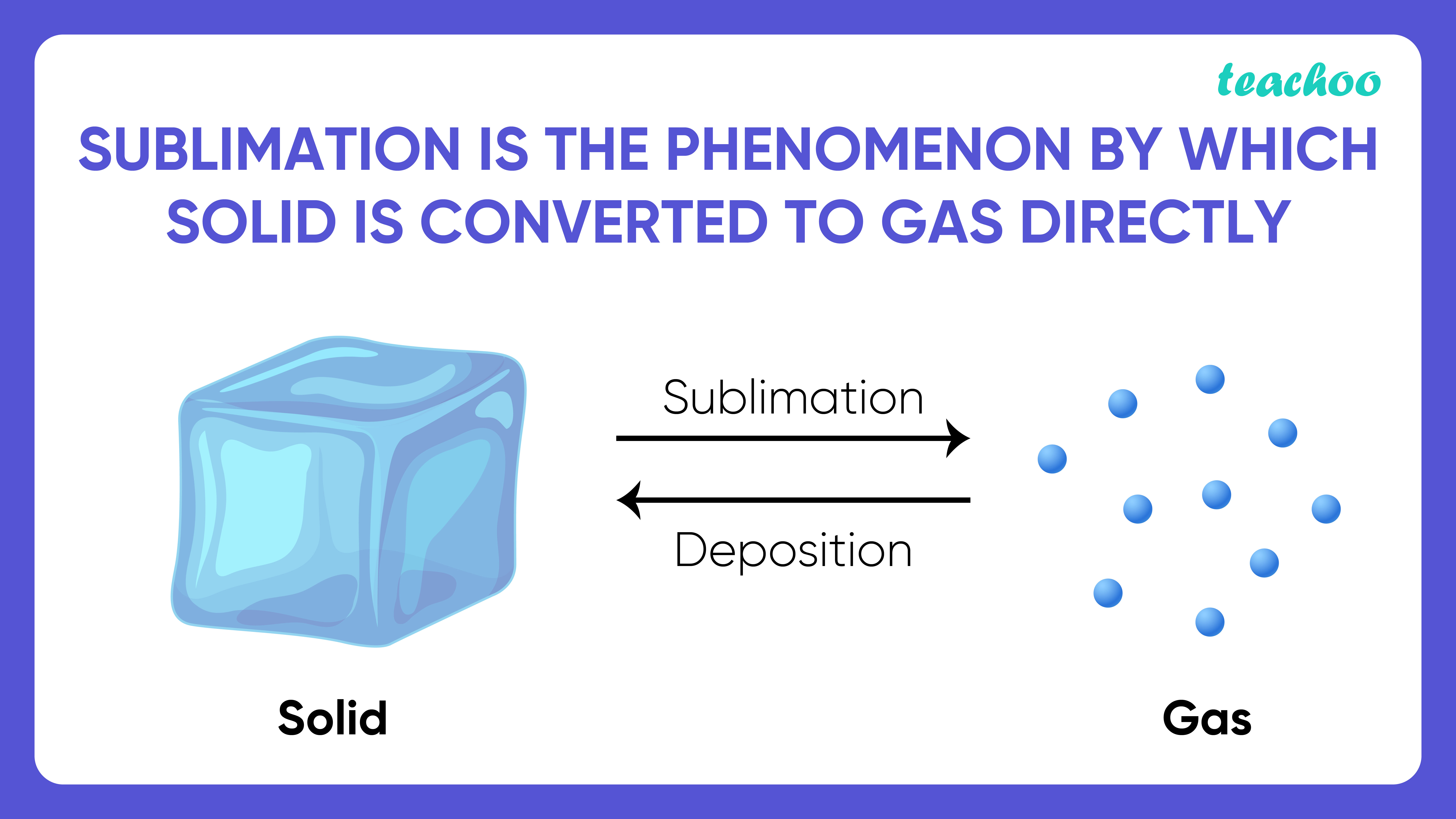

So, you might be wondering, what exactly is this "sublimation" thing people talk about, and how does it even apply to making a cool dye patch hat? Well, it is a rather neat trick that happens in the world of physics, actually. It is when a solid material, like the special ink we use for printing, turns directly into a gas without ever becoming a liquid first. Think about it, usually ice melts into water before it evaporates into vapor, right? With sublimation, that middle liquid step is just completely skipped, which is pretty interesting, if you ask me.

This whole process is set off by absorbing warmth. When a substance takes in enough heat, it gives its tiny parts, the molecules, enough get-up-and-go to break free from their neighbors and float away as a vapor. It is kind of like when dry ice, which is frozen carbon dioxide, seems to just disappear into a foggy mist at normal room temperatures; it is not melting, it is sublimating. This unique change is what makes it so special for creating a vivid sublimation dye patch hat.

For making a dye patch hat, this means we are taking a solid dye, putting it on a piece of paper, and then, with some serious heat and pressure, getting it to turn into a gas. This gas then sinks right into the material of the patch. It is not just sitting on the surface, like paint would; it is actually becoming part of the fabric itself. This is why the colors can be so bright and the designs so crisp, and it makes for a very smooth feeling patch on your hat, too it's almost as if the design was always there.

- Embracing The Beauty Of Long Hair Framing The Face

- Unveiling The Wealth Of Yasmine Bleeth A Look At Her Net Worth

- Exploring The Legacy Of The Iran Mens National Soccer Team

- Tate Mcrae The Rising Star Of Pop Music

- Unveiling The Iconic Blueface Hair A Trendsetters Journey

The Science Behind Sublimation for a Dye Patch Hat

The core idea behind sublimation for your dye patch hat is a physical change, a bit like how water can turn into steam. But here, we are talking about a solid dye. This dye, when it gets really warm, does not melt into a gooey liquid. Instead, it jumps straight to being a gas. This is a special kind of phase shift, and it happens under just the right warmth and pressure conditions. It is a process that takes in warmth, making it an "endothermic" change, meaning it needs energy to happen, like when you heat water to boil it, only different, obviously.

Imagine those tiny dye particles. When they soak up enough warmth, they get so much energy that they just cannot hold onto each other anymore as a solid. They break free and fly around as gas molecules. This is what allows them to move from the paper they were printed on directly into the fibers of the patch material. It is a very direct way to get color into something, which is pretty cool for a sublimation dye patch hat, you know.

This conversion between solid and gas, with no liquid stage in between, is what makes the whole thing work so well for printing. It means you do not have to worry about liquid inks bleeding or smudging. The gas goes right into the material, cools down, and then becomes a solid again, but now it is inside the fabric. This is a key reason why a sublimation dye patch hat ends up looking so good and lasting for a long time, essentially because the dye is now a part of the material, not just on it.

How Heat Makes Your Dye Patch Hat Designs Appear

So, the real secret sauce in making a sublimation dye patch hat is the warmth. It is the main thing that kicks off this whole process. You start with your design printed on a special paper using those unique sublimation dyes. Then, this paper, along with the blank patch material, gets put into a heat press. This press applies both high warmth and steady pressure, which is very important for the dye to do its thing.

As the warmth builds up, those solid dyes on the paper begin to change. They do not melt; they just turn into a gas. This gas then gets pushed into the fibers of the patch material by the pressure from the heat press. The fibers of the patch are usually made of polyester or have a polyester coating, because this material is really good at absorbing the gaseous dye. It is almost like the fabric opens up to let the color in, if you can imagine that.

Once the warmth is taken away and the patch cools down, the gaseous dye turns back into a solid. But now, it is inside the fabric fibers, not on the paper anymore. This means the design is truly embedded within the patch, which then gets put onto your hat. This is why a sublimation dye patch hat feels so smooth; there is no raised texture from the print, and the colors are very vibrant and seem to pop. It is a pretty clever way to get a design onto something, honestly.

Why Choose a Sublimation Dye Patch Hat?

There are quite a few good reasons why someone might pick a sublimation dye patch hat over other types of custom hats. One of the biggest advantages is how incredibly lasting the designs are. Because the dye becomes a part of the material itself, it is not going to crack, peel, or fade away easily, unlike some other printing methods that just sit on the surface. This means your custom hat will keep looking good for a very long time, which is something people really appreciate, you know.

Another big plus is the level of detail and color you can achieve. Since the dye turns into a gas, it can create very smooth color changes and sharp images. You can get really complex pictures, photographs, or designs with many different shades and gradients, all looking fantastic on your patch. This opens up a lot of creative doors for what you can put on a sublimation dye patch hat, making it pretty versatile for all sorts of ideas, whether for a business or just for fun.

And then there is the feel of it. Because the dye is integrated into the fabric, the patch remains soft and flexible. There is no stiff, raised feeling that you sometimes get with other printing methods. It is just a smooth part of the hat, which makes it very comfortable to wear. So, for a custom sublimation dye patch hat, you get not just great looks but also a pleasant feel, which is a definite win-win situation, basically.

Long-Lasting Colors on Your Sublimation Dye Patch Hat

The staying power of the colors on a sublimation dye patch hat is truly one of its standout features. Unlike traditional screen printing or vinyl applications where the design sits on top of the fabric, sublimation embeds the color right into the fibers. This means the design is not just a layer that can be scratched off or worn away with repeated washing or sun exposure. It is genuinely a part of the material itself, which is pretty neat.

Think about your favorite t-shirt that has a printed design. Over time, after many washes, you might notice the print starting to crack or fade, losing its original brightness. With a sublimation dye patch hat, because the dye has chemically bonded with the fabric, it is much more resistant to these kinds of wear and tear. The colors stay vibrant and true, even after a lot of use and being out in the sun. This makes them a very good choice for things like sports teams, work uniforms, or just everyday wear where you want your custom item to hold up, honestly.

This durability also means less worry about special care instructions for your hat. While you should always treat your custom items with some care, a sublimated patch is generally quite forgiving. It is not going to run or bleed, and the colors will not wash out. So, when you pick a sublimation dye patch hat, you are really choosing something that is built to last and keep its good looks for a long time, which is a pretty solid benefit, I think.

What Kinds of Designs Can You Put on a Sublimation Dye Patch Hat?

When it comes to designs for a sublimation dye patch hat, the possibilities are, well, pretty wide open. Because the process handles color and detail so well, you are not limited to just simple shapes or a few colors. You can really let your imagination run free. Do you have a photo you want to put on a patch? A complex logo with tiny details? A design that uses many different shades of the same color? All of these can look fantastic with sublimation.

This method is especially good for designs that have a lot of different colors or smooth color transitions, like a sunset or a picture of a pet. Unlike some other printing methods that might struggle with blending colors seamlessly, sublimation can create really fluid and natural-looking gradients. This means your images will look very professional and eye-catching on your sublimation dye patch hat, almost like a piece of art.

So, whether you are thinking about creating hats with detailed artwork, company branding with specific color schemes, or even just fun, quirky patterns, a sublimation dye patch hat can probably handle it. It is a really flexible way to get your vision onto a patch, giving you a lot of freedom to express yourself or your brand in a way that looks great and feels good too. You can get some truly unique pieces this way, basically, with a lot of personal touch.

Are Sublimation Dye Patch Hats Right for Everyone?

While sublimation dye patch hats offer a lot of great things, like vibrant colors and lasting designs, they might not be the perfect fit for absolutely everyone or every situation. One thing to keep in mind is the material of the hat itself, or more specifically, the patch. Sublimation works best on materials that are made of polyester or have a polyester coating. If you are set on a hat made of 100% cotton, for example, a sublimated patch might not be the ideal choice, as the dye will not bond as well with natural fibers, which is important to consider.

Also, because the dye becomes part of the fabric, you usually start with a light-colored patch material, typically white. This allows the colors of your design to really show up true and bright. If you try to sublimate onto a dark-colored patch, the colors of the dye will be affected by the dark background, and they might not appear as vivid or accurate. So, if your heart is set on a black patch with a bright design, you might need to look at other printing methods or consider a different approach for your sublimation dye patch hat, perhaps using a white patch on a dark hat.

However, for most people looking for custom, colorful, and long-lasting hat designs, a sublimation dye patch hat is a really strong contender. It offers a premium look and feel that many other methods just cannot match, especially for complex or photographic designs. It is a very popular choice for a reason, and it is honestly worth considering if the material and color requirements fit what you are looking for, you know.

Caring for Your Sublimation Dye Patch Hat

Taking care of your sublimation dye patch hat is, in general, pretty straightforward, thanks to how the sublimation process works. Because the dyes are embedded into the fabric, they are quite resistant to washing out or fading. You do not have to be overly worried about the design coming off, which is a nice peace of mind, really. However, a little gentle care can help make sure your hat looks good for as long as possible.

When it comes to cleaning your hat, it is usually best to hand wash it with a mild soap and cool water. Avoid using harsh chemicals or bleach, as these could potentially affect the fabric of the hat itself, even if the sublimated patch is quite robust. Gently scrub any dirty spots, then rinse thoroughly. Allowing your sublimation dye patch hat to air dry is also a good idea. This helps maintain the shape of the hat and prevents any potential shrinking or damage from high heat, which can sometimes happen in a dryer.

You probably will not need to iron the patch, given its smooth finish, but if the hat itself gets wrinkled, use a low heat setting and maybe a pressing cloth to protect the patch area. The main thing to remember is that the design itself is very durable, so your focus should be on caring for the hat's overall structure and material. With just a little bit of attention, your sublimation dye patch hat will continue to be a vibrant and comfortable accessory for a long time, and stuff.

In short, a sublimation dye patch hat uses a cool process where dye turns directly into a gas to embed itself into a patch, which then goes onto your hat. This makes for designs that are super colorful, very detailed, and incredibly long-lasting because the dye is part of the material. It works best on polyester or polyester-coated patches, usually light in color, and it is a pretty great option for custom headwear that stands out and feels good to wear, requiring just a little gentle care to keep it looking its best.

- Unveiling The Life Of Marcus Rosners Wife

- Unveiling The Life Of Simon Cowells Son

- Exploring The Life Of Billy Bob Thorntons Brother

- Unraveling The Professional Lives Of Taylor Swifts Parents

- Unveiling The Life And Legacy Of Jesse Minter

/sublimation-of-dry-ice-co2-solid-co2-changes-directly-from-solid-to-gas-128108785-5768263e5f9b58346ad1d386.jpg)

Sublimation Definition (Phase Transition in Chemistry)

What is Sublimation and Cricut Infusible Ink? | Crafting Spree

What is Sublimation? - 5+ Examples with Diagram - Teachoo